LAMILL Coffee Roasting Tour & Cupping Experience

Last week, I received the chance to attend and learn more about the roasting process at LAMILL Coffee! Their warehouse and office is located in Alhambra, and everything from the receipt of the beans to the packaging occurs here.

Process: Farmer > Milling > Transport > Roasting > Coffee Shop > Barista

LAMILL gets most of their beans from Central and South America, and each bag comes as heavy as 130 lbs to 150 lbs. The beans are a light greenish brown before roasting, and it had a earthy scent that smelled subtly like vegetables. There is a natural protective coating covering the beans called parchment, and after it is dried in the sun, the outer coating is removed and placed into bags to be shipped to the LAMILL warehouse.

The beans are then placed in a bucket elevator (below photo) which holds up to 132 lbs of beans. The elevator shoots the beans up through a shaft and takes the beans to a 60 kilo drum roaster that continually rotates over 400 degrees (420 for a dark roast). Every couple minutes, the roasters look and smell the coffee to make heated adjustments as time affects acidity. There is also a roast tracker that tracks every roast that they've had for quality purposes. For example, a longer roast would result in a chocolate caramel like smell, whereas a lighter roast is more lemon-y and citrus-y.

During the roasting process, air is incinerated and exits clear with no smoke. There is also a chaff byproduct that flakes off during the roasting process which is shown in the photos below. As the beans roast, you can hear crackling which indicates the moisture building up as well as the steam pressure. Sounds almost like popcorn popping in the microwave but more distinct! The crackling is used as a time marker at what stage the beans are at!

For small batch coffee, a smaller roaster (12 kilos) is used, and it can hold up to only 26 lbs at a time. The more expensive coffee is roasted here. The lightest roast can be as fast as 10 minutes, and the darkest roast will take up to 17 minutes.

After the beans are roasted, it is packaged into smaller pound bags and ready to ship!

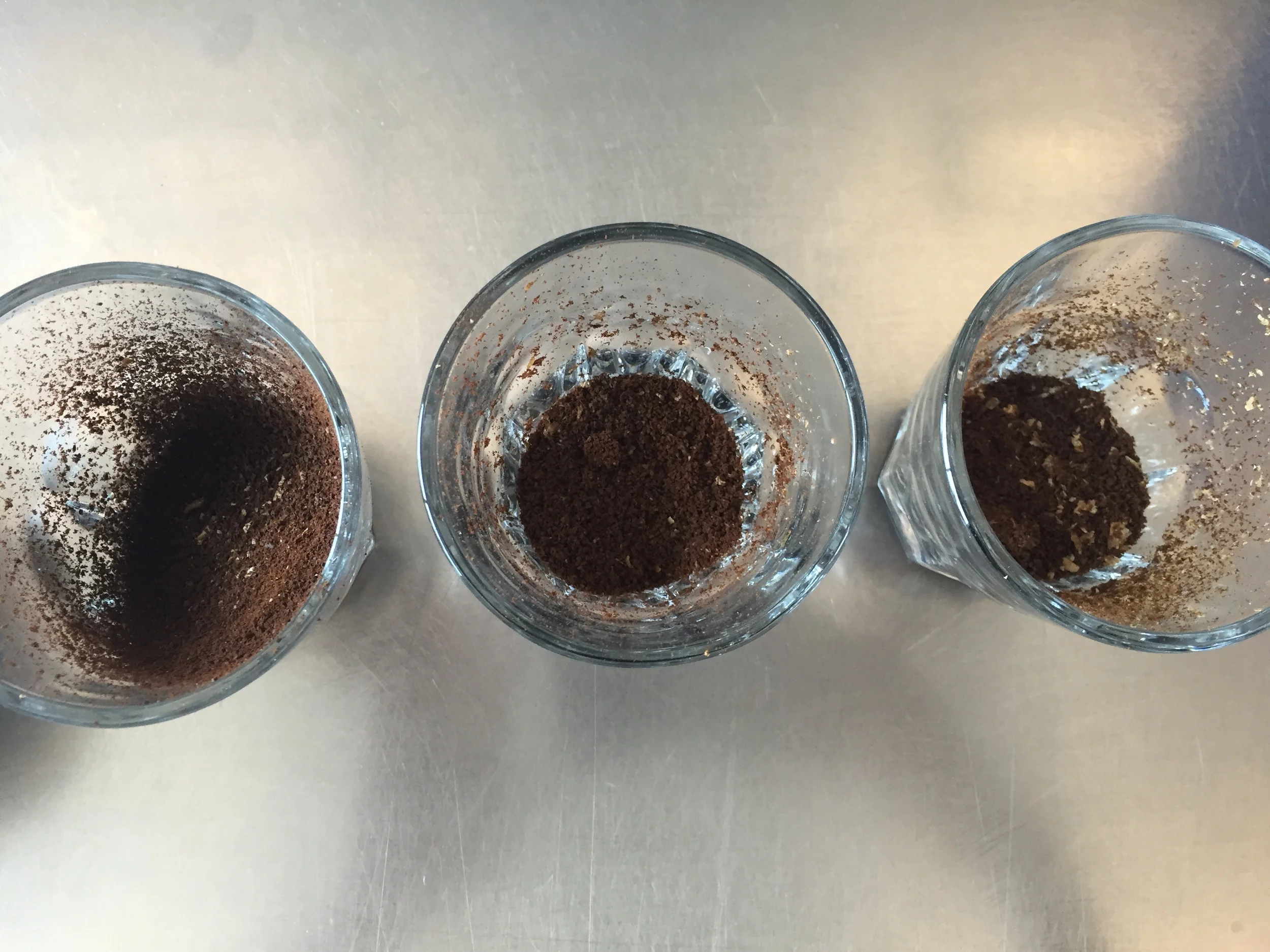

After watching the roasting process, we were taken to the cupping room to try the different types of beans! We received a light, medium, and dark roast to try. This part was super interesting as the process is extremely different from how normal coffee is brewed! At this part, John, the director of coffee, taught us the appropriate way to brew.

After grinding the beans, he used filtered water at 195-205 degrees to brew the coffee. Distilled water has no taste, and hard mineral la water is no good as there are too many minerals. At 204 degrees, co2 is forced out by the water, and crusting occurs.

We were then taught how to "slurp" the coffee- you take a spoon and after breaking the crust, you slurp in the small sip of coffee to get the full flavor all throughout your mouth. The louder the slurp, the better! We repeated this process for every roast after cleaning our spoon in the water cups!

My favorite ended up being the light roast as it was more vibrant and citrus in flavor. I had such a fun and educational time learning about the roasting process and the various beans! Thank you John and LAMILL Coffee for giving us a roasting tour and showing us how to cup!